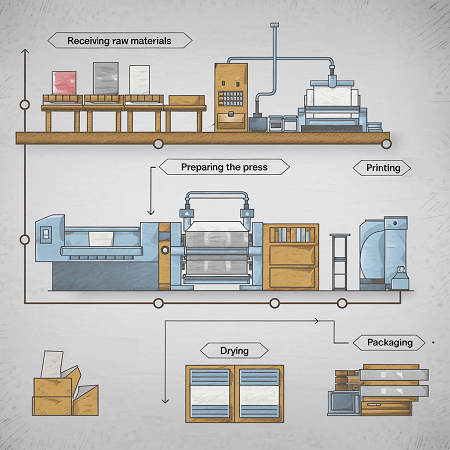

The printing process is a complex and multi-stage cycle of activities that leads from the idea to the final product. In any professional print shop like ours, accuracy, quality and timeliness are key elements that guarantee the success of any project. To give you an idea of what this process looks like, here are the ten most important steps that make up the journey from design to the finished print.

1. Before the printing process begins – consultation and needs analysis

Every printing process begins with a thorough analysis of the client’s needs. It is first necessary to establish what the expectations are for the final product, including format, print run, colours, materials, and lead times. This is a key moment that allows us to tailor the entire process to individual requirements, ensuring that we achieve the desired end result.

2. Graphic design preparation

Graphic design work follows in the next step. Depending on whether the client provides a finished design or requires graphic support, our graphic design team can design professional material from scratch. This stage covers not only aesthetics, but also technical issues such as adapting the design to the requirements of print, including appropriate resolution, margins, and preparing the files for print.

3. Acceptance of the project

Once we develop the graphic design, the acceptance stage follows. The design goes to the client, who has the opportunity to familiarise himself thoroughly with its appearance and functionality. This is the last moment to make any amendments or changes. Once the customer approves the design, it is no longer possible to modify it, which is why it is so important to check every element carefully.

4. Choice of materials

Choosing the right materials is a step that significantly affects the final appearance and durability of the print. The variety of available materials, such as different types of paper (matt, glossy, uncoated, eco-friendly) or other media (e.g. foil, canvas) allows a perfect match to the nature and purpose of the project. The choice of materials depends on the specifics of the order and expectations regarding the end result.

5. Prepress and RIP process

As part of the prepress stage, the design goes to the prepress department, where the RIP process takes place. This is a high-tech step in which graphic files are converted into raster format, allowing every detail to be reproduced precisely. This is a key moment where we set all the printing parameters, such as resolution, colour separation and raster, i.e. the positioning of the printing points. At this stage, we also make a so-called proof, which is a trial print that allows us to assess how the design will look in its final form.

6. The actual printing process

Once the design is ready, the actual printing stage follows. Depending on the specific order, we use different printing techniques, such as offset, digital or screen printing. Offset printing is particularly suitable for large print runs, offering high quality and low unit costs. Digital printing, on the other hand, is ideal for smaller runs where fast turnaround times are important. Screen printing, on the other hand, is common for printing on non-standard surfaces such as textiles or plastics.

7. Varnishing, finishing and drying

Once the material is printed, it is possible to refine it by UV varnishing, foiling, embossing or gilding. These processes add elegance to the prints and increase their durability. After finishing, the prints are dried, which is an extremely important stage. Drying can perform naturally or in special industrial dryers, which speed up the process and ensure that no imperfections such as ink smudging or page gluing appear on the surface of the prints.

8. Cutting and processing

After printing and drying, we process the prints, including, above all, cutting. Thanks to high-precision cutting machines, we cut each print precisely. Depending on the project, additional processing processes such as creasing (paper folding), perforating, stapling or folding can also be carried out, which give the final shape to the printed material.

9. Quality control, very important in printing process

Each print goes through a quality control check before dispatch. This process includes a thorough check that all print parameters match the design and that the materials meet the highest quality standards. The check includes an evaluation of the colours, the accuracy of cropping and the physical condition of the print. In case of any discrepancies, the material is printed again to ensure complete customer satisfaction.

10. Packaging and delivery

The final step in the printing process is the packaging and delivery of the finished materials. Depending on the customer’s preference, the order can be collected in person, sent by courier or delivered directly to the specified address. All materials we pack carefully to ensure safe transportation. What’s more, the print shop also offers international shipping, allowing to deliver worldwide, regardless of destination.

Printing process – summary

The printing process is a complex and precise operation that requires advanced technology and careful execution at every stage. From needs analysis to design to delivery – every step matters so that the final product meets the highest quality standards. Thanks to our professional approach and state-of-the-art technologies, our printing house can carry out even the most demanding projects, both in the domestic and international markets.