UV Varnish is one of those techniques that take printing to the next level. Anyone who wants to attract the attention of their customers and protect their materials at the same time should take a closer look at it. What makes UV varnishing so popular? Why are so many companies opting for this technique? Here are 5 key facts that will help you understand how UV varnishing works and what benefits you can derive from it.

1. How does UV Varnish work?

The UV varnishing process is based on coating printed materials with a special varnish that is cured by ultraviolet rays. In practice, it looks like the varnish is applied to specific areas of the design – either the whole or a selection of them – and immediately exposed to UV light. This allows the curing process to take place almost immediately, resulting in a durable and impressive finish.

UV varnish can be applied in various forms: as glossy, matte, or even with a 3D effect. Each of these options allows you to give your printed materials a unique character. This works particularly well on business cards, catalogs, flyers and covers.

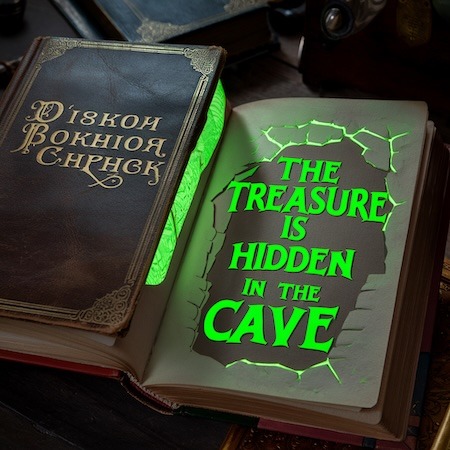

2. UV Varnish highlights details and is eye-catching

One of the greatest strengths of UV varnishing is its ability to highlight key design elements. Selective varnishing allows you to highlight your logo, header or other important graphic elements. UV varnish makes the colors more intense and gives the whole thing an elegant look.

Using this technique also helps you stand out from the competition. In a world where new promotional materials arrive every now and then, it is important that our designs attract attention at first glance. UV varnishing provides just such an opportunity.

3. Durability and protection are other advantages

If you want your advertising materials not only to look nice, but also to last a long time, UV varnishing is a hit. Varnish protects prints from abrasion, scratches and mechanical damage. This is especially important for heavily used materials, such as product catalogs or offer folders.

In addition to mechanical protection, UV varnish also protects the surface from moisture and dirt. While it doesn’t make printed materials waterproof, it significantly increases their resistance to everyday challenges.

4. Selective or total varnishing – which to choose?

UV Varnish comes in two main versions: overall and choice. The choice between the two depends on the effect you want to achieve.

- All-over varnishing – here the varnish covers the entire surface of the material, giving it a consistent and elegant appearance. This option is perfect for catalogs, flyers or folders.

- Selective varnishing – in this case the varnish is applied only to selected elements of the design, such as logos, photos or important texts. This is an excellent way to draw attention to key details and add character to the project.

Both options allow you to achieve a professional result, but each has its own specific applications. If you have any doubts, it’s worth consulting with a printer who can help you choose the best solution for your project.

5. Why bet on UV varnish in your projects?

UV Varnish is not only a technique that improves the aesthetics of printed materials, but also an investment in quality and durability. By choosing this method, you gain:

- Professional appearance – materials with UV varnish look more prestigious, which positively affects the perception of your brand.

- Damage resistance – the varnish protects against everyday wear and tear, making your materials look new for longer.

- Increased marketing effectiveness – exposing key design elements makes your materials more compelling and attracts the attention of the recipient.

UV Varnish is a solution that combines functionality with aesthetics. Whether you need elegant business cards or durable folders, this technique will work in any situation. If you want your designs to impress and last for years to come, UV Varnish is a great choice.

Have questions or want to try UV varnishing on your projects? Get in touch with us! As a printing house, we have a lot of experience with various projects and will be happy to advise you on the best solutions. We will make sure that your materials look perfect!