The world of printing has its own rules, and complicated printing terms can make it difficult to complete a project. Do you know the difference between CMYK and Pantone? Why are bleeds so important? Learn 10 key printing terms that will help you avoid mistakes and ensure a professional end result.

1. CMYK – the basic color space in printing

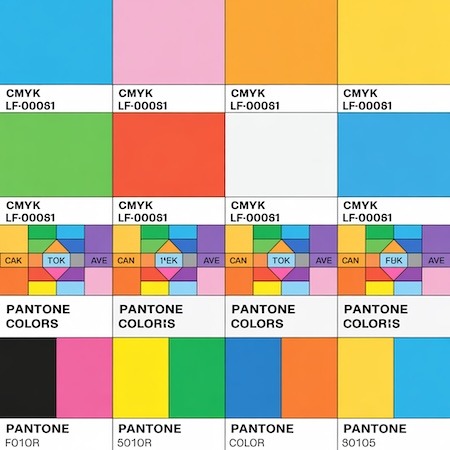

Printing terms often start with CMYK – an acronym for the four colors of ink: Cyan (C), Magenta (M), Yellow (Y) and Black (K – “Key”). Unlike RGB (used in monitors), CMYK has a narrower color gamut, so some bright colors may look different on print.

Why is this important?

- Designs for printing should be created in CMYK.

- RGB colors may lose intensity after conversion.

2. Pantone – a system of precise colors

Pantone (PMS – Pantone Matching System) is a template that ensures perfect color matching regardless of the printer. It is used when an exact shade is needed (for example, in company logos).

Example:

Coca-Cola is using a specific Pantone shade of red to make its branding consistent around the world.

3. DPI (Dots Per Inch) – density of dots per inch

DPI determines the resolution of printing. The standard is 300 DPI – lower values can cause blurring or pixellosis.

When to pay attention to DPI?

✔ For large-format projects (such as banners), you can use a lower DPI (150-200) because they are viewed from a distance.

✖ In printing business cards or flyers, always stick to 300 DPI.

4. Bleeds – margin of safety

A bleed is an extra area (usually 2-3 mm) beyond the target format that prevents white lines when trimmed. If the design has a background, it must “extend” into the bleed.

A mistake that costs money:

The client did not add bleeds to the business card design. After trimming, white edges appeared – the entire print run was suitable for discarding.

5. Paper weight – thickness in practice

The grammage (given in g/m²) determines the weight and stiffness of the paper:

- 80-100 g/m² – thin paper (e.g. for flyers)

- 250-350 g/m² – business cards, invitations

- Above 350 g/m² – cardboard (e.g., packaging)

6. Proofing – color sample

Proof is a test print that shows what the final colors will look like. It is worth ordering, especially for large print runs.

Types of proofs:

- Digital – fast and cheap, but less accurate.

- Printing – simulates the end result (e.g. Matchprint).

7. Laminating – print protection

Laminating (glossy/matte) protects the print from abrasion and moisture. Popular in:

- Business cards

- Restaurant menu

- Catalog covers

8. Creasing – preparation for folding

Creasing is a cut in the paper that makes it easier to bend without cracking. It is used, for example, in:

- Invitations

- Cardboard packaging

- Brochures

9. Folding – the method of folding

Folding is the term for various methods of bending sheets, such as:

- Parallel waveguide – a leaflet folded “on an accordion”.

- Cross fold – for example, in tourist maps.

10. RIP (Raster Image Processor) – printer software.

A RIP is a program that converts a graphics file into instructions for a printing machine. Its quality depends on, among other things.:

- Color fidelity

- Sharpness of details

- Printing speed

Summary

Knowing printing terms makes it easier to communicate with the printer and helps avoid costly mistakes. Remember especially:

✔ CMYK and Pantone – choosing the right color space.

✔ Bleed and DPI – crucial to print quality.

✔ Proofing – the last moment for corrections.